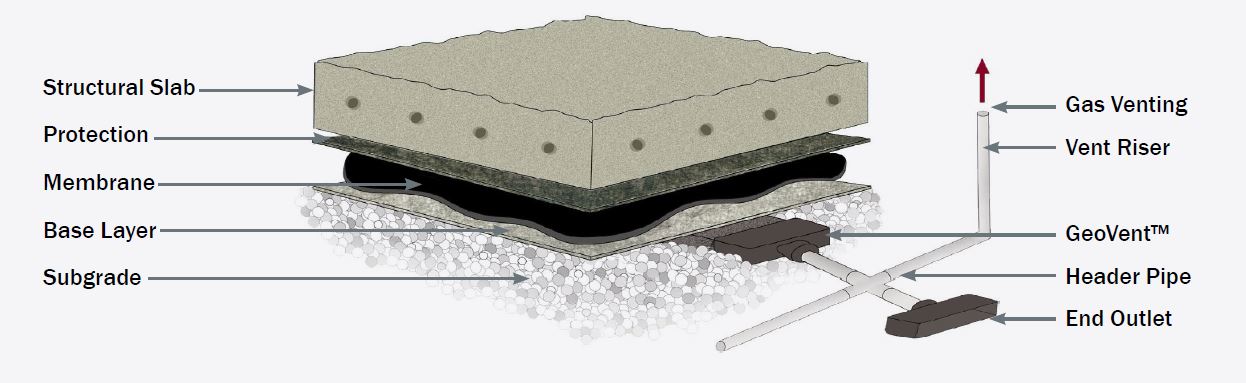

Venting systems are typically installed in conjunction with a vapor barrier when volatile or explosive gases are present. GEOVENT is a low-profile pressure relief, trenchless collection and venting system designed to improve venting efficiency and reduce installation costs. GEOVENT has several advantages over trenched installations and can be used as an “active” or “passive” venting system depending on the specific project. Used in conjunction with LIQUID BOOT® vapor barrier, GEOVENT can alleviate the accumulation of gas vapors under the slab.

GEOVENT is a 3-dimensional vent core that is wrapped in a non-woven, needlepunched filter fabric and is used with GEOVENT end outlets, GEOVENT reducers, and pipework components to form part of a passive and active sub-slab venting system.

GEOVENT can be installed directly onto the subgrade to eliminate trenching and potential interference or damage to existing underground utilities.

| Components | Description |

| GEOVENT | 1 ft x 165 ft roll |

| GEOVENT End Outlet | GEOVENT - 100 mm pipe conversion |

| GEOVENT Reducer | 100 mm pipe - 50 mm pipe conversion |

| Fabric Tape | Hard cast fiber reinforced tape |

Venting systems should be properly designed to adequately relieve pressure and reduce gas concentrations from beneath the structure. CETCO can provide assistance with GEOVENT layouts and design grids as well as detail drawings for these types of systems.